As the volume of deliveries and the geographic scale of your last mile logistics grows, your delivery network will become increasingly complex.

How tangled is your last mile delivery network? Across our customers, we see many operating complex webs of internal fleets and external carriers (3PLs), each with their own specialisms, constraints, coverage and costs.

This becomes very difficult to manage in a centralised manner without the appropriate infrastructure in place. Choosing the best last mile delivery management platform for your business will help you maintain real-time visibility and control over your entire delivery network.

In this blog, we’ll attempt to untangle the Gordian Knot that is modern multi-carrier and 3PL logistics – a complicated problem that requires a bold solution.

We’ll consider:

-

The advantages of third party logistics for quickly and cost-effectively growing your last mile delivery business

-

A look at the different sorts of fleets you might choose to partner as you scale

-

The new challenges of planning and managing deliveries across a multi-hierarchical fleet

-

The limitations of legacy systems and the benefits of modern SaaS platforms for the management of last mile delivery networks

As the volume of deliveries and the geographic scale of your last mile logistics grows, your delivery network will become increasingly complex.

How tangled is your last mile delivery network? Across our customers, we see many operating complex webs of internal fleets and external carriers (3PLs), each with their own specialisms, constraints, coverage and costs.

This becomes very complicated to manage in a centralised manner without the appropriate infrastructure in place. Choosing the best last mile delivery management platform for your business will help you maintain real-time visibility and control over your entire delivery network.

In this blog, we’ll attempt to untangle the Gordian Knot that is modern multi-carrier and 3PL logistics – a complicated problem that requires a bold solution.

We’ll consider:

-

The advantages of third party logistics for quickly and cost-effectively growing your last mile delivery business

-

A look at the different sorts of fleets you might choose to partner as you scale

-

The new challenges of planning and managing deliveries across a multi-hierarchical fleet

-

The limitations of legacy systems and the benefits of modern SaaS platforms for the management of last mile delivery networks

3PL – Logistics for Rapid Scale

Whether you started your last mile operations with internal fleet resources or working with a single 3PL, chances are that you will need to branch out as the volume of your deliveries grows. Adding additional internal resources requires huge capital investment because of the cost of purchasing vehicles. A global giant like Amazon can afford to acquire 100,000 electric vehicles over the next ten years.

But for most, that sort of approach isn’t financially viable. After all, the last mile makes up as much as 53% of total shipping costs, according to Business Insider. So anything that can be done to cut this cost is going to be most welcome. For most, that means working with a combination of 3PLs, allowing for that huge capital expenditure to be shifted into more manageable ongoing operational outgoings.

At a basic level, external carriers are well equipped to help businesses deliver more affordably to more people. This is why leveraging 3PLs makes sense for senders looking to grow their deliveries while decreasing their costs. Third-party logistics providers deliver considerable key benefits:

- Access to flexible delivery capacity

- Usage of greener vehicles without any capital outlay

- Instant access to specialist delivery services, such as big and bulky deliveries by trained installers

- Consolidation of deliveries

- Increased geographical coverage

- Reduced fixed costs

- Improved service levels and flexibility

Scale Brings Complexity to Last Mile Logistics

Working with a combination of internal fleets and specialist 3PLs promises lower operating costs if each can be leveraged in the most efficient manner. Using your internal fleets for deliveries close to your hubs, for example, or preferring a green logistics provider with electric or two-wheeled vehicles for deliveries in and around Ultra Low Emissions Zones.

That’s great on paper. But orchestrating it becomes a huge headache and it’s this pain that many retailers and delivery companies have been increasingly facing as their volumes have skyrocketed over the last couple of years and through the pandemic.

The more value you wish to unlock from the various assets that make up your delivery network, the more granularity you need to go into in planning. Think about these two scenarios for instance:

- A rush hour delivery was delayed because the size of the van made finding parking on a one-way street difficult, especially as the van could only be unloaded from the left but the address was on the right of the street.

- A van was stuck for 15 minutes in heavy inner city traffic heading between two addresses located on either side of a large park.

In isolation, such issues might appear small, but they can have a compound effect that quickly accumulates, especially when you extrapolate similar issues across every delivery round you’re managing.

- It all adds up to cumulative delays that have a knock-on effect on the rest of the day’s deliveries and increases the risk of failed deliveries later on

- More idle time with the engine running means more fuel burned and a higher carbon footprint for the same number of deliveries

- That also means higher operational costs in an industry where margins are already incredibly squeezed.

Scale Brings Complexity to Last Mile Logistics

Working with a combination of internal fleets and specialist 3PLs promises lower operating costs if each can be leveraged in the most efficient manner. Using your internal fleets for deliveries close to your hubs, for example, or preferring a green logistics provider with electric or two-wheeled vehicles for deliveries in and around Ultra Low Emissions Zones.

That’s great on paper. But orchestrating it becomes a huge headache and it’s this pain that many retailers and delivery companies have been increasingly facing as their volumes have skyrocketed over the last couple of years and through the pandemic.

The more value you wish to unlock from the various assets that make up your delivery network, the more granularity you need to go into in planning. Think about these two scenarios for instance:

- A rush hour delivery was delayed because the size of the van made finding parking on a one-way street difficult, especially as the van could only be unloaded from the left but the address was on the right of the street.

- A van was stuck for 15 minutes in heavy inner city traffic heading between two addresses located on either side of a large park.

In isolation, such issues might appear small, but they can have a compound effect that quickly accumulates, especially when you extrapolate similar issues across every delivery round you’re managing.

- It all adds up to cumulative delays that have a knock-on effect on the rest of the day’s deliveries and increases the risk of failed deliveries later on

- More idle time with the engine running means more fuel burned and a higher carbon footprint for the same number of deliveries

- That also means higher operational costs in an industry where margins are already incredibly squeezed.

Legacy Systems Betray the Advantages of Third Party Logistics

In the first of our examples, being able to ensure that the delivery was loaded onto a smaller van or bike that could park on the right side of the road in a tighter spot would have solved the challenge.

For the second, a two-wheeled vehicle that could cut through the park would make those deliveries in half the time and with less fuel consumption or carbon emissions.

But how can you optimise your deliveries with that degree of accuracy? For a modern delivery network, there are hundreds of variables to consider across each package, driver, vehicle, fleet and carrier.

Spreadsheets and legacy systems such as premise-based software inherently lack flexibility and scalability by design: they are holding organisations back in their efforts to rapidly grow.

Consumers now have very high expectations for their delivery experience. At the same time, these customers won’t differentiate between a retail brand and its delivery partners. In terms of customer experience, the last mile has become a crucial customer touchpoint for brands. A buttery smooth customer experience through optimized delivery partnerships and planning is something legacy systems simply cannot provide.

Greater Clarity and Control

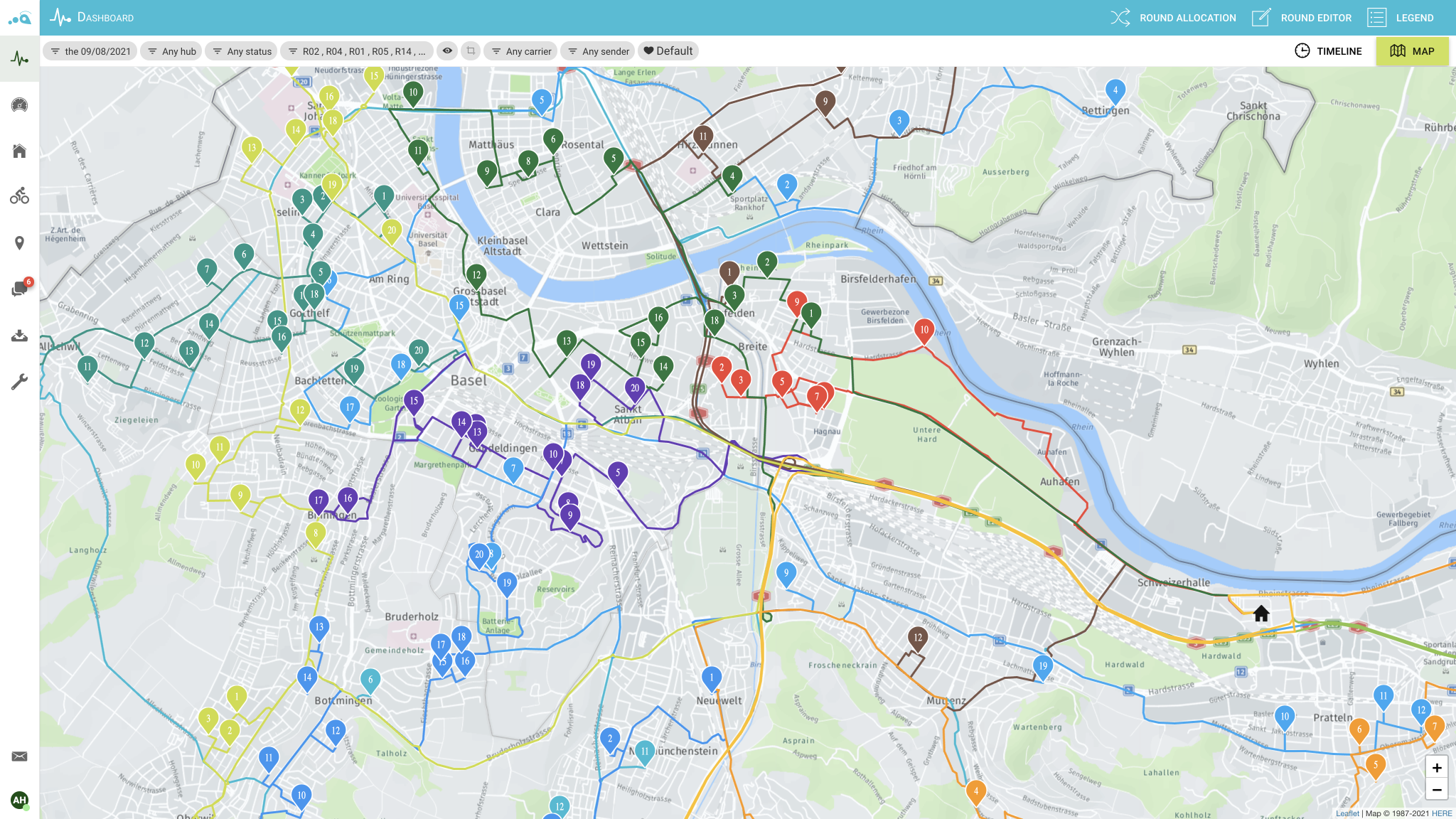

Today’s sophisticated supply chains require software tools that are capable of handling multiple warehouses, operations and transport partners. Last mile delivery management platforms for fleet management and route planning organise this in a centralized, scalable and efficient way.

Through the use of advanced algorithms to automatically optimise routes and improve efficiency, it is possible to optimise allocation of delivery jobs across fleets and carriers in a way that takes into account all of those hundreds of variables.

Intelligent SaaS platforms integrate with existing provider platforms, so there is a single interface that acts as a control room for your entire last mile logistics operation.

Greater Clarity and Control

Today’s sophisticated supply chains require software tools that are capable of handling multiple warehouses, operations and transport partners. Last mile delivery management platforms for fleet management and route planning organise this in a centralized, scalable and efficient way.

Through the use of advanced algorithms to automatically optimise routes and improve efficiency, it is possible to optimise allocation of delivery jobs across fleets and carriers in a way that takes into account all of those hundreds of variables.

Intelligent SaaS platforms integrate with existing provider platforms, so there is a single interface that acts as a control room for your entire last mile logistics operation.

Check out our new state of the industry report: Last Mile Logistics 2021-22

3 Benefits of Using a Last Mile Delivery Management Platform

1. Seamless integration with 3PL platforms

Larger third-party logistics providers have their own route-planning software. Through their open API, platforms like Urbantz allow you to pass on delivery requirements in a standardized format and display real-time status updates from different providers through a single dashboard.

2. Smart delivery allocation across carriers

Advanced fleet management SaaS provides the opportunity to assign delivery jobs across the appropriate 3PL carrier or internal fleet. The AI will take into account delivery timing and other carrier-specific constraints to find the best delivery option for every package – improving costs simultaneously.

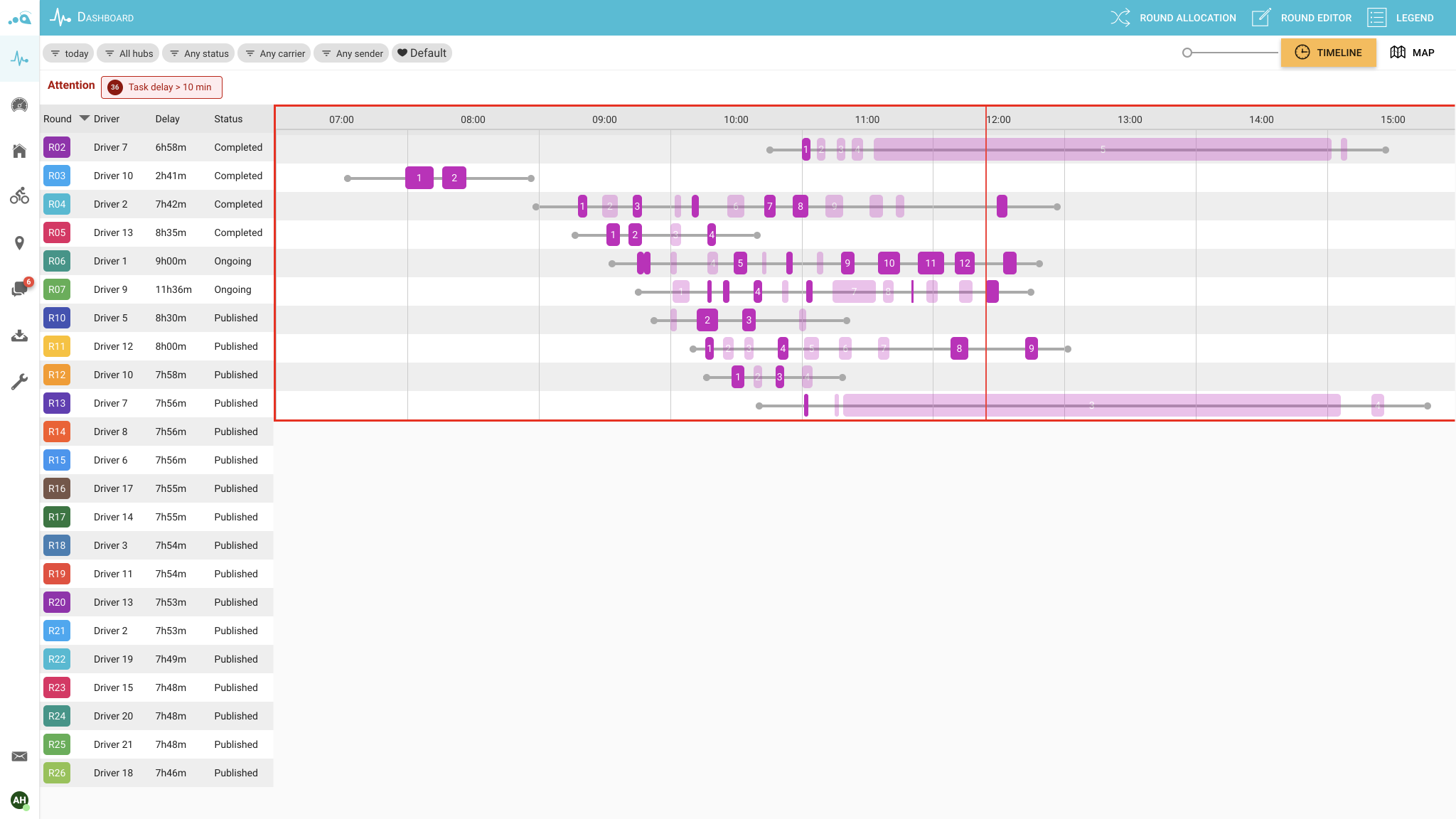

3. Management by exception

Overseeing thousands of daily deliveries through an algorithm allows you to shift from containment to anomaly detection. Zooming in on deliveries that aren’t going according to plan, allows organizations to focus on their customer experience proactively and spot errors early on.

3. Management by exception

Overseeing thousands of daily deliveries through an algorithm allows you to shift from containment to anomaly detection. Zooming in on deliveries that aren’t going according to plan, allows organizations to focus on their customer experience proactively and spot errors early on.